Steam Boiler Treatment

Steam boilers suffer mainly from scaling deposits and corrosion in the boiler and condensate system. If left untreated, this leads to energy and water waste, as well as equipment failure.

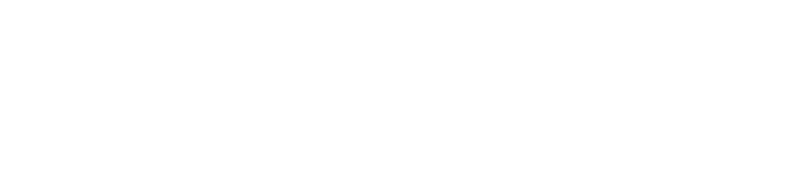

STEAM BOILER MAKEUP WATER TREATMENT

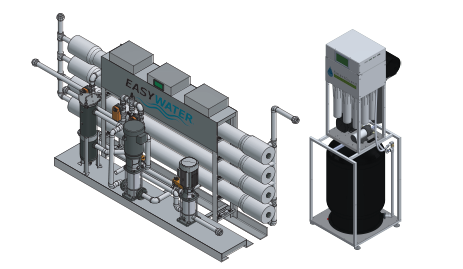

Makeup water to a steam boiler should always be treated. We typically recommend either our SmartGuard RO System or SimplySoft ion exchange softener.

Although a softener removes most of the hardness, it does not remove alkalinity. As a result, the alkalinity becomes carbonic acid in the condensate return piping and lowers the pH, causing corrosion. More amine-type chemicals are then needed to raise the pH. SmartGuard RO removes almost all the minerals in water, including the alkalinity. SmartGuard will reduce the need for certain chemicals and more importantly reduces the blowdown as well as propensity to build scale in the boiler

Less Blowdown = Energy Savings

Every gallon that is blown down in a steam boiler means that the makeup gallon must be heated to boiling. Surface blowdown of boilers is done based on conductivity using a conductivity controller. When the mineral content or conductivity of the water reaches the set point of the controller, it opens a bleed valve and blows boiler water down the drain. Since the mineral content of the SmartGuard RO makeup water will be a small fraction of salt-softened water, there will be considerably less blowdown and makeup, significantly reducing energy consumption.

TREATMENT OF THE FEEDWATER

Whether a SmartGuard RO System or SimplySoft ion exchange softener is used to treat the boiler makeup water, we recommend continually treating the boiler feedwater with the No-Salt Conditioner. This helps eliminate scaling deposits in the boiler and acts as a backstop in case the SmartGuard RO or SimplySoft softener fails. To be clear, if the RO or softener system fails and hard untreated water is made up to the boiler, the No-Salt Conditioner treatment will help reduce scaling in the boiler until the makeup treatment comes back online but likely won’t eliminate it. Therefore, it is a secondary or backstop treatment and should never be the primary treatment.

CHEMICAL TREATMENT PROGRAM

All steam boilers should be under the expertise of a competent chemical company who is monitoring and making corrections for things like hardness, pH, oxygen, cycles of concentration, etc.

Find out more about our treatment options for steam boilers by contacting us today at 1-888-766-7258, or by filling out our free estimate form below.

Related Products

Request A Quote

Looking for your local sales rep? Click Here

Call EasyWater directly at 1-888-766-7258, or fill out the form below to get a quote for your project.

(Need a residential quote? Click Here)