Prevents and reduces scale and biofilm

Children’s Medical Center: Cooling Tower Water Treatment System

Children’s Medical Center: Cooling Tower Treatment System

| Project: |

Children’s Medical Center |

| Location: | Plano, TX |

| EasyWater Rep: | Texas Air Systems |

| Scope of Work: |

(3) 890 Ton Cooling Towers |

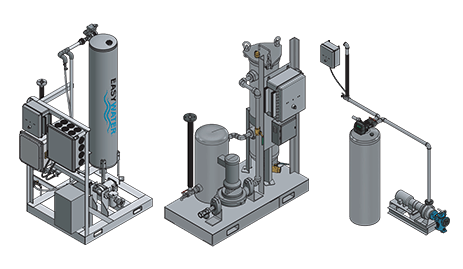

| EasyWater Equipment: |

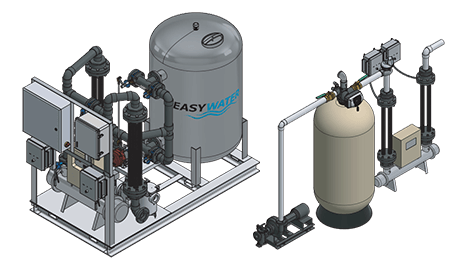

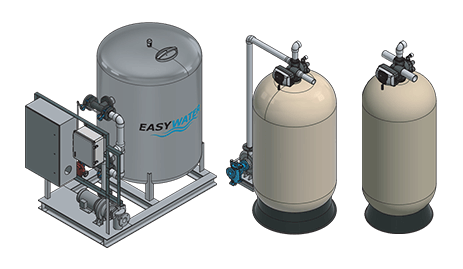

Model CTF-500-S Skid Mounted Treatment System |

Problem

During the renovation of the CEP, the (3) 890 ton cooling towers at the Children’s Medical Center accumulated significant debris, including dust, pollen, and construction materials. This led to several issues:

- Reduced Heat Transfer Efficiency: Deposits on heat exchange surfaces impeded heat transfer, reducing the overall efficiency of the cooling system.

- Increased Maintenance Requirements: The presence of debris necessitated frequent cleaning and maintenance, leading to increased operational costs and downtime.

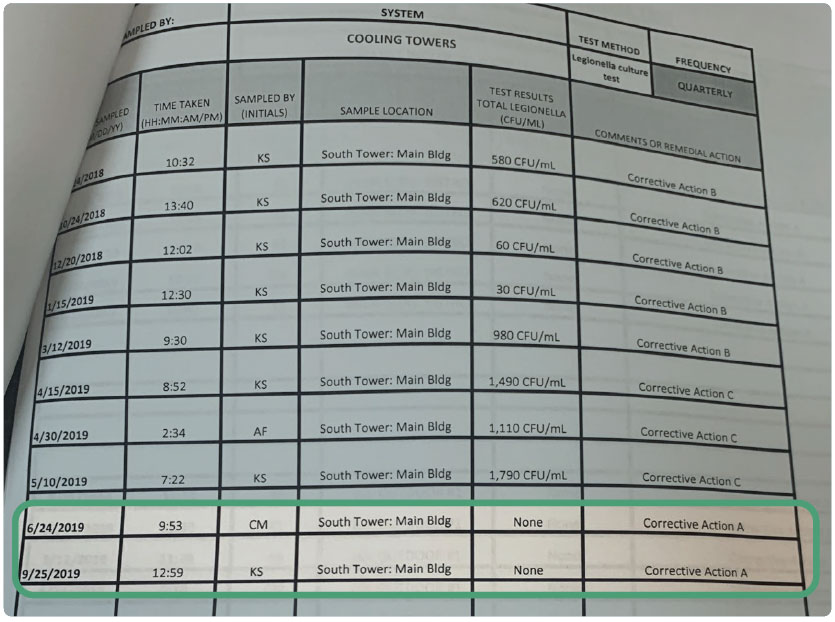

- Health and Safety Concerns: Sediment and debris in cooling tower systems can harbor harmful bacteria, such as Legionella, posing serious health risks to patients and staff.

A separator had been used in the past for filtration, but it failed to maintain the required water clarity and system cleanliness.

Solution

To address these challenges, the decision was made to install the CTF-500-S treatment system, a state-of-the-art solution specifically designed for cooling tower applications. The CTF-500-S treatment system incorporates several advanced features:

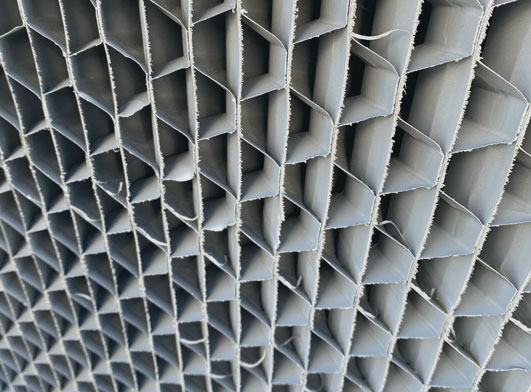

- SedimentShield Sub-Micron Filtration: Utilizes proprietary media capable of removing particles and bacteria down to sub-micron levels, significantly reducing turbidity and microbial presence in the water.

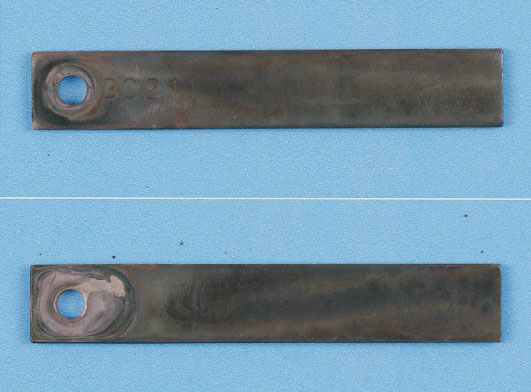

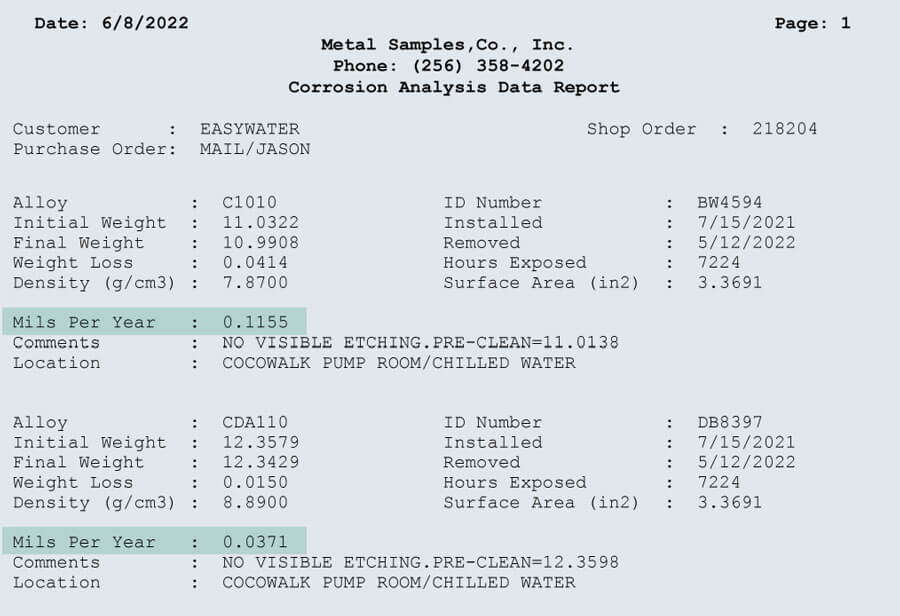

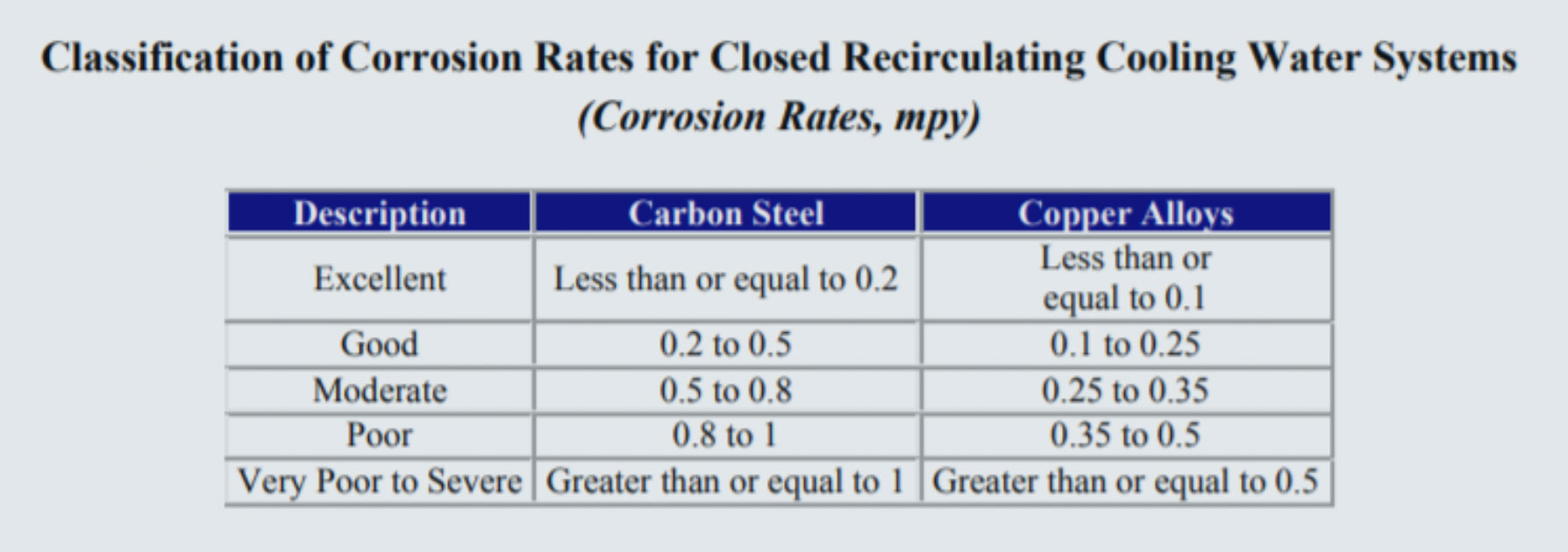

- Ultraviolet (UV) Sanitization: Employs UV light to effectively kill bacteria on contact, minimizing the need for chemical biocides and reducing corrosion rates.

- No-Salt Conditioners: Prevent and remove hard water scale deposits and biofilm, enhancing heat transfer efficiency and reducing the risk of bacterial growth.

RESULTS

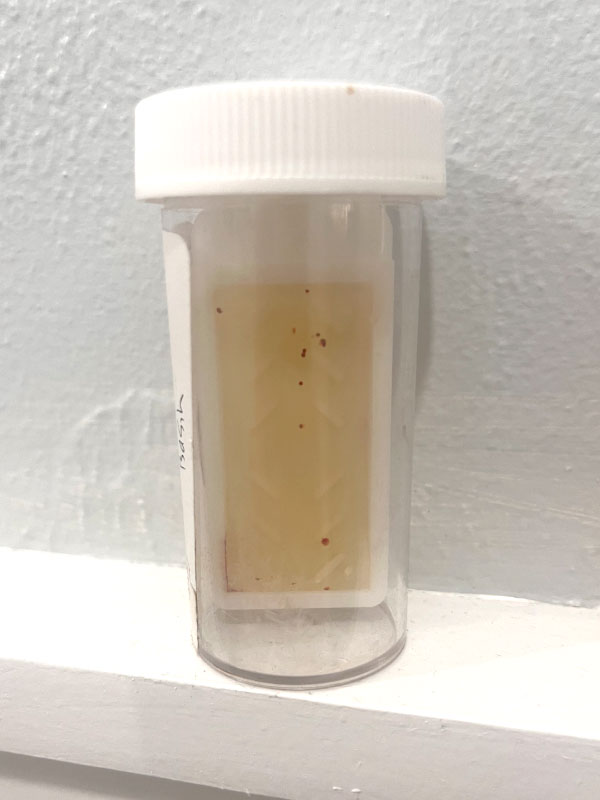

Since the installation of the CTF-500-S treatment system, the Children’s Medical Center has observed several notable improvements:

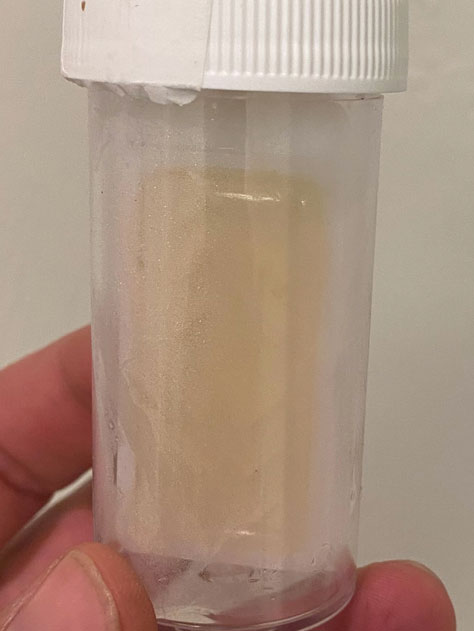

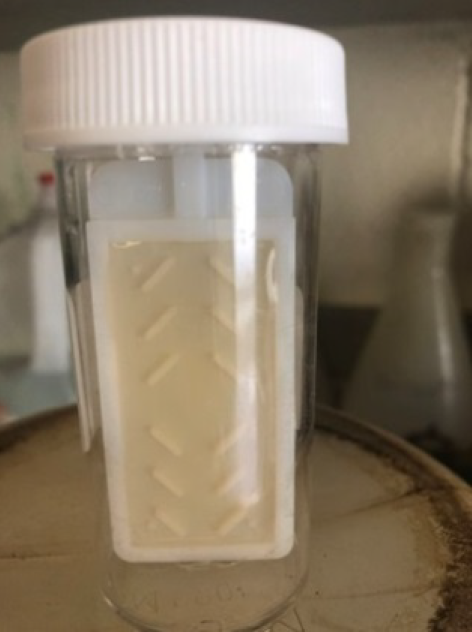

- Enhanced Water Clarity: The SedimentShield submicron filtration resulted in significantly clearer water, cleaner sumps and lower bacteria counts.

- Reduced Maintenance Frequency: CTF’s filtration effectiveness has decreased the need for frequent cleaning and maintenance, leading to cost savings and reduced downtime.

- Improved Energy Efficiency: By preventing scale and biofilm formation, the system has enhanced heat transfer efficiency, contributing to lower energy consumption.

- Health and Safety Compliance: The significant reduction in bacterial counts, which saves chemical costs and reduces the risk of Legionella, has ensured compliance with health and safety standards, safeguarding the well-being of patients and staff.

The implementation of the CTF-500-S treatment system at the Children’s Medical Center has successfully addressed the water quality challenges associated with cooling towers. The advanced features of the system have led to improved operational efficiency, reduced maintenance requirements, and enhanced health and safety compliance. This case study underscores the importance of selecting appropriate filtration solutions in medical facilities to maintain optimal cooling system performance and ensure a safe environment.

Are you looking for cooling tower water treatment for your facility?

We manufacture and offer a complete line up of industrial water treatment solutions. Please give us a call at 1-888-766-7258, or use the form below to reach out to us, so one of our experts can help you with your project.

Need a quick quote for a project?

Related Products

Recent Projects

Request A Quote

Looking for your local sales rep? Click Here

Call EasyWater directly at 1-888-766-7258, or fill out the form below to get a quote for your project.

(Need a residential quote? Click Here)