Prevents and removes scale and biofilm

Henniges Automotive: Closed Loop Chilled Water Treatment

Henniges Automotive: Closed Loop Chilled Water Treatment

| Project: | Henniges Automotive |

| Location: | New Haven, MO |

| Scope of Work: | Closed Loop Chilled Water Treatment |

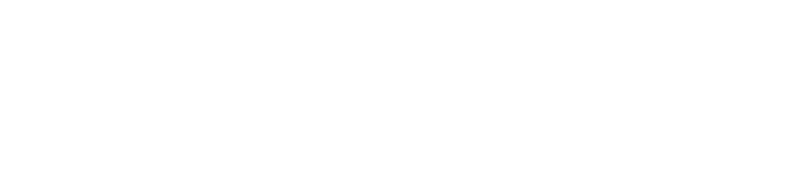

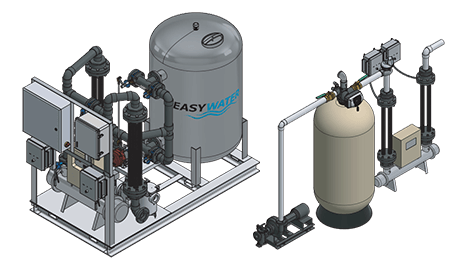

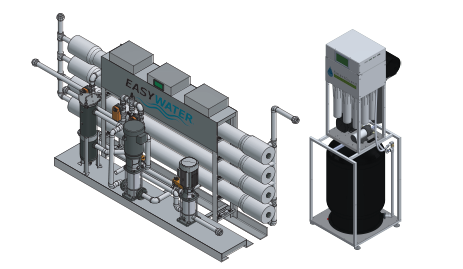

| EasyWater Equipment: | (1) CLC-1000-S – Series C Closed Loop Treatment System |

Problem

Henniges Automotive is a leading global supplier of highly engineered automotive sealing and anti-vibration solutions. Their New Haven, MO, facility has 8 closed loop chilled water systems with vented tanks used for process cooling. The vented tanks cause high levels of dissolved oxygen, creating major corrosion to equipment, piping and other components.

Steve Cronin, Finishing Engineer at Henniges, said the dissolved oxygen caused:

- “sludge, sediment and corrosion problems”

- “clogging of thermal control units and heat exchangers”

- “piping [to be] lined with deposits”

- “the water will turn to a brown sludge if not flushed often”

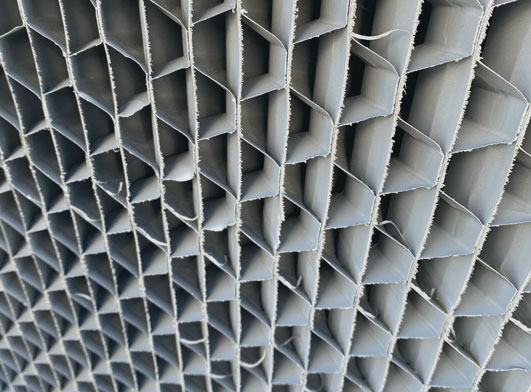

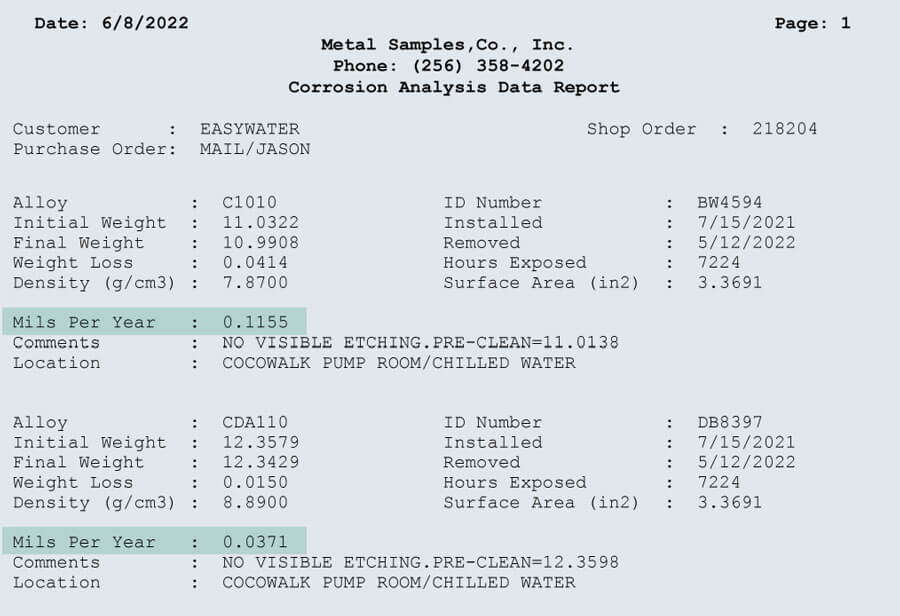

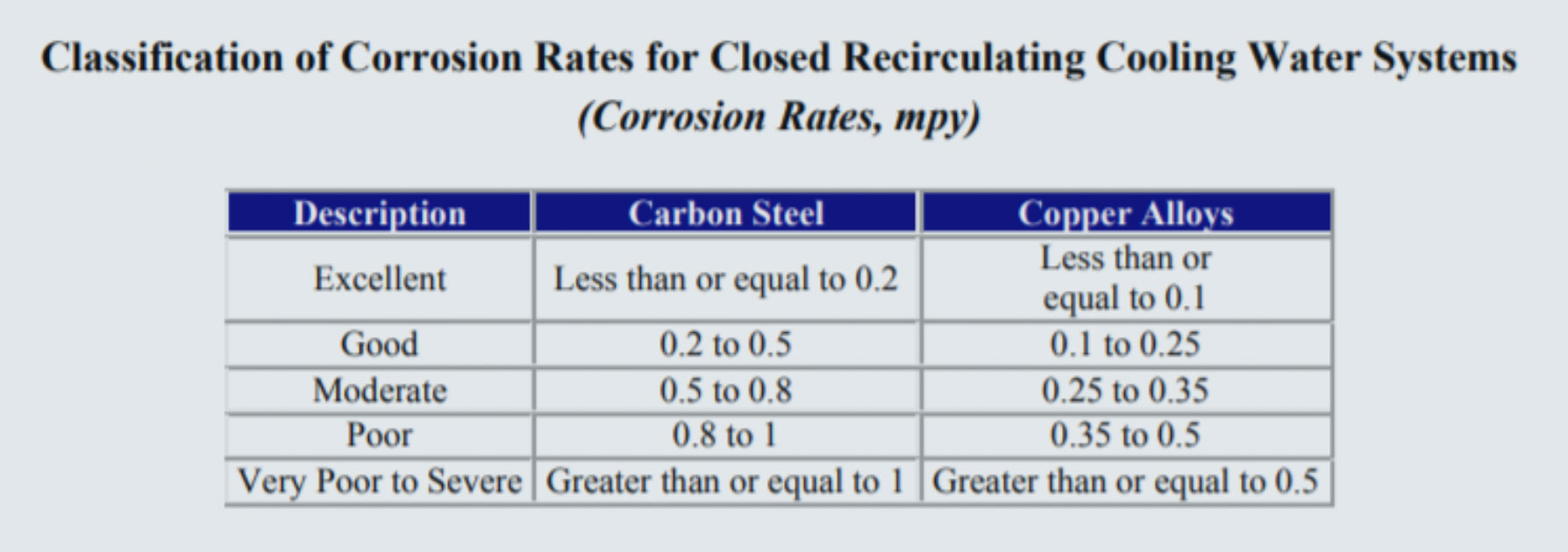

Deposits and dissolved oxygen in the water were tested at a certified third party lab. The EDS analysis of the deposit was found to be “composed primarily of zinc and iron [from the Closed Loop System].” Dissolved oxygen was 9.13Mg/L. The lab results confirmed the problem to be corrosion caused by dissolved oxygen.

Solution

EasyWater Series C Model CLC-1000-S (Closed Loop Chilled – Skid-Mounted). This automatic backwashing, skid-mounted system provides cost effective, low maintenance, non-chemical treatment for closed loops. This unique, three-part solution contains:

- Proprietary filtration media that continuously removes dissolved oxygen

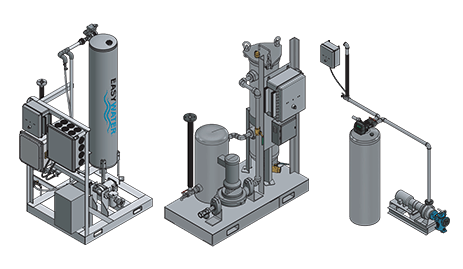

- Sub-micron, self-backwashing filter for the removal of sediment, debris, and bacteria

- EasyWater No-Salt Conditioners to prevent and remove insulating deposits, as well as biofilm

and bacteria

RESULTS

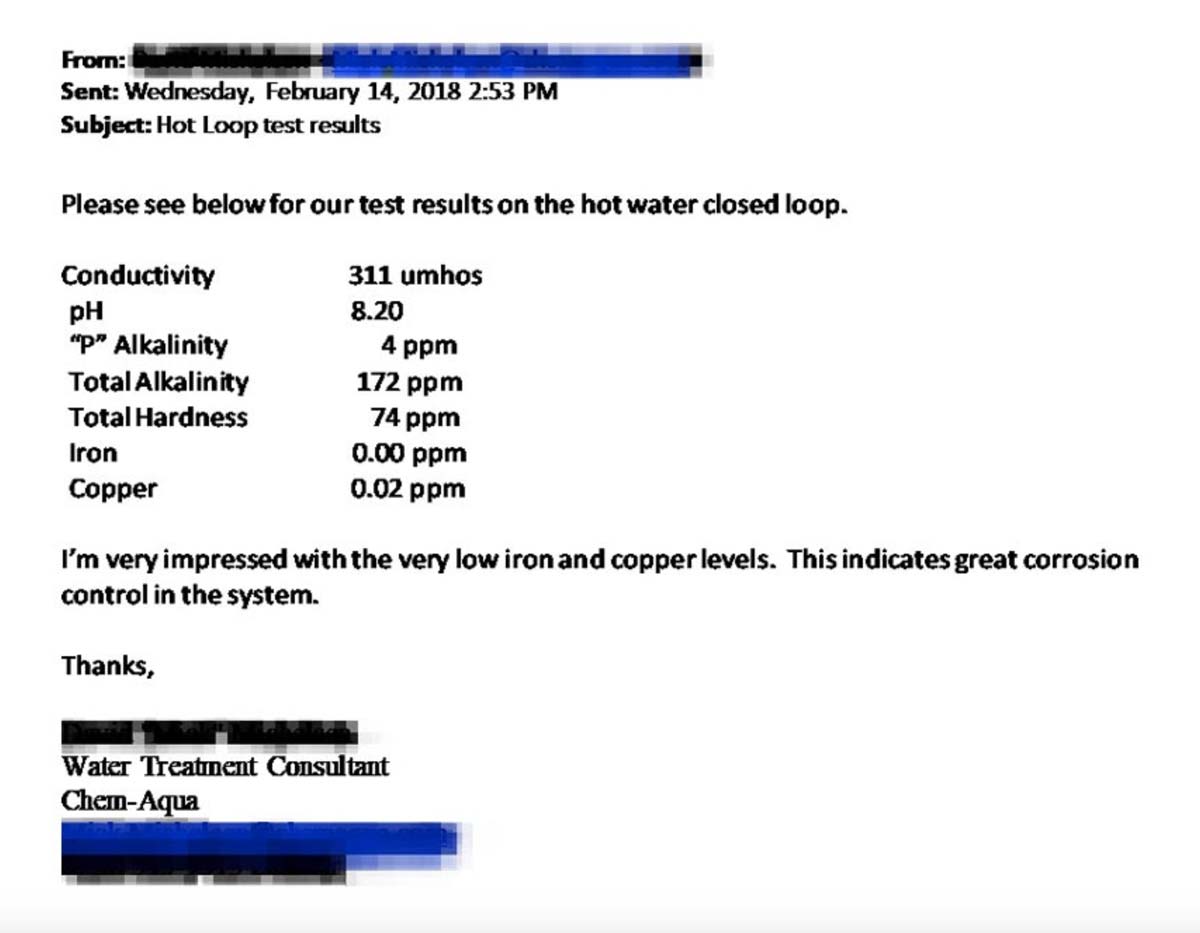

Three weeks later, the dissolved oxygen was dramatically lower, and there wasn’t a single clogged thermal control unit despite the loop never having been flushed.

Since installation of the Series C System:

- The dissolved oxygen level has been extremely low

- Henniges hasn’t had a single thermal control unit clog

- They haven’t had to flush the system

Henniges is so pleased with the results, they installed a second CLC-1000-S for another closed loop at their New Haven facility. They are also obtaining quotations for treating additional closed loops with Series C, as well as cooling towers with EasyWater’s CTF System.

Are you looking for cooling tower or closed loop water treatment for your facility?

We manufacture and offer a complete line up of industrial water treatment solutions. Please give us a call at 1-888-766-7258, or use the form below to reach out to us, so one of our experts can help you with your project.

Need a quick quote for a project?

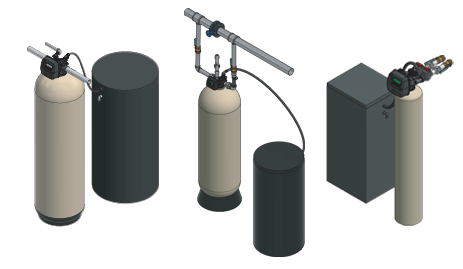

Related Products

Recent Projects

Request A Quote

Call us today at 1-888-766-7258, or fill out the form below to get a quote for your project.

(Need a residential quote? Click Here)